Henry Fibered Aluminum Roof Coating Dry Time

Pro grade 586 fibered aluminum roof coating is a premium fibered aluminum coating for new or aged smooth surface bur modified bitumen membranes aged galvanized metal roofs and new asphalt emulsion that forms a tough brilliant reflective surfacing.

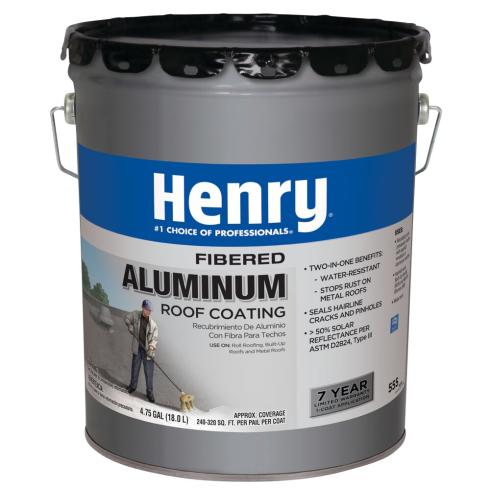

Henry fibered aluminum roof coating dry time. Apply a base coat of henry 107 asphalt emulsion sealer and dampprooferat a rate of 3 4 gallons per 100 square feet. Do not use with saturated felts. Henry 555 fibered aluminum roof coating is a premium fibered aluminum coating that forms a tough reflective weathering surface. Allow to cure 3 to 4 months before applying a reflective fibered aluminum coating.

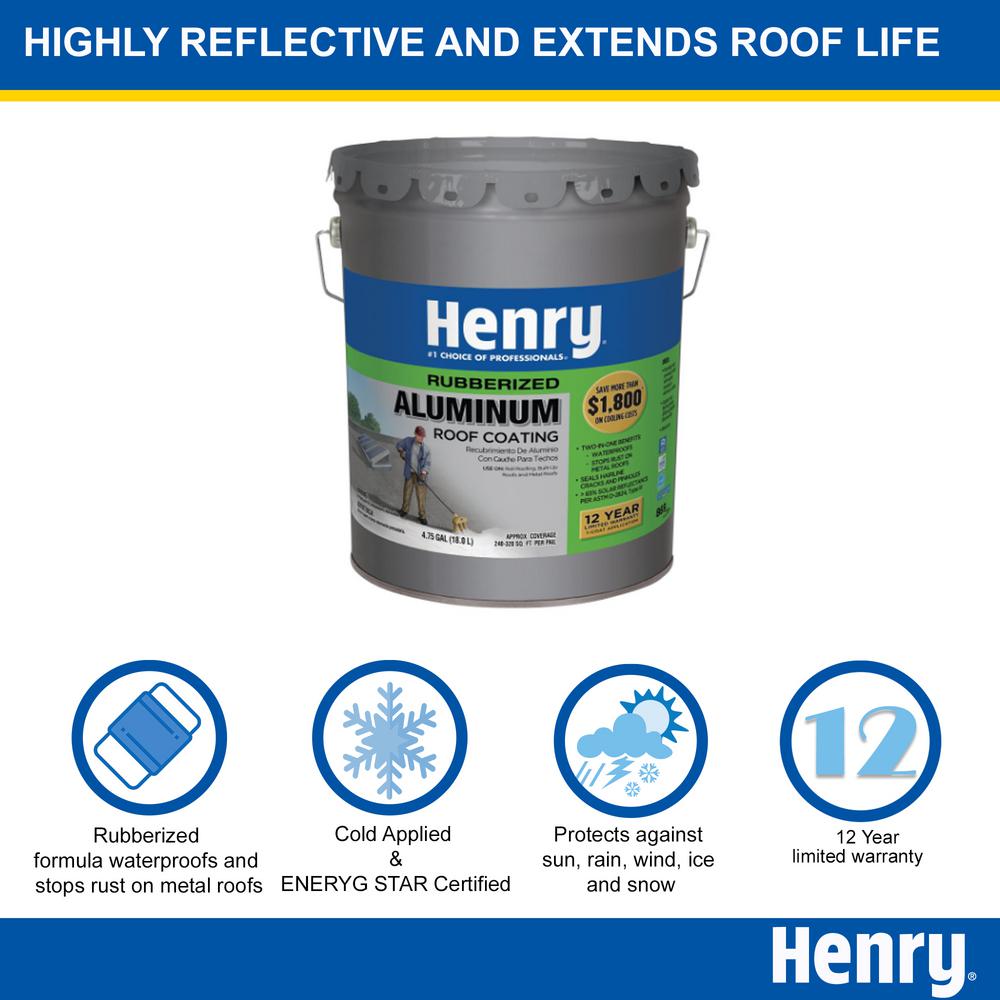

This coating is designed for use on the roofs of barns homes garages and mobile homes. It can help decrease air conditioning costs by reducing heat transfer through the roof. On metal roofs remove rust by wire brushing. It can decrease heating and air conditioning costs and keeps the inside temperature of a building up to 20 f cooler in summer.

Henry 555 aluminum roof coating is an ultra premium fibered aluminum roof coating that forms a shiny tough reflective surface. Stops rust on metal roofs. Do not use with solvent sensitive insulation wood shingles of any kind or wood flashings. Usually in 3 7 good drying days.

This coating is designed for use on the roofs of barns homes garages and mobile homes. This coating is not recommended over gravel rubber or pvc sheet roofing shingles of any kind or old roofs that are too dry and brittle to. It can decrease air conditioning costs and can lower the inside temperature of buildings up to 20 f cooler in the summer.