How Do Stop Corrosion On Metal Roofs Using Copper Finals

If you can successfully separate the metal from oxygen moisture and other environmental factors you can stop corrosion.

How do stop corrosion on metal roofs using copper finals. 7 common issues that could affect a metal roof knowing about the problems that could occur on a metal roof system will help prevent issues from the very start resulting in less time and money necessary for repairs. Corrosion prevention techniques can be generally classified into 6 groups. Clean monthly to achieve the best results. The paint on metal roofs will fade when the sun bakes the top coat off of the painted metal.

Church roofs school roofs facades mansard roofs and other colored metal roofs are a major part of the image of the building. With a little bit of advance planning you can prevent metal roof corrosion. Why do metal roofs fade. When metal roof corrosion begins the material begins to turn brittle.

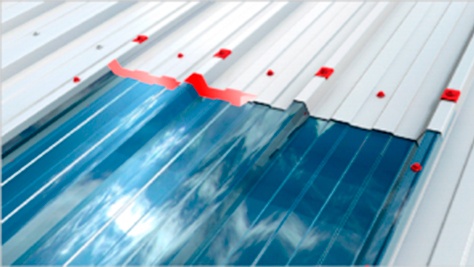

While trees and heavy debris can damage even the sturdiest and highly durable standing seam variants metal roof corrosion is a problem that is second to none. Metal roofing can withstand multiple hailstorms the most severe winters and heavy rainstorms. Restore the color and luster of your faded roofs with everbrite and renew the image of your building. Corrosion prevention can take a number of forms depending on the circumstances of the metal being corroded.

Run the strips under a row of shingles at the roof ridge making sure that at least 2 inches of the copper are exposed. Slide the copper strip under the shingle edge until you hit the nails holding. However i have seen dozens of roofs with a combination of cedar shingles and copper flashings where the flashing has lasted as long as the cedar shingles. This will prevent any type of corrosion happening to the copper as well as keeping the metal shiny.

Be careful of copper runoff from plumbing pipes that may leak onto zinc roofing material. A the soluble tannins in cedar can cause corrosion of copper flashing and the textbooks discourage using copper with cedar. This takes time but if done thoroughly copper corrosion will never be a problem. Plating paint and other coatings can help to reduce the speed and severity of corrosion by creating a barrier between the metal fastener and its environment stager says.

They re separated on the chart and galvanic corrosion will show quickly. With most copper objects regular cleaning using a salt or vinegar and baking soda paste is the answer. In virtually all situations metal corrosion can be managed slowed or even stopped by using the proper techniques.