Hot Mopped Evaloy Fleeceback Roof System

It serves to protect the base sheet on your roof and keep it watertight.

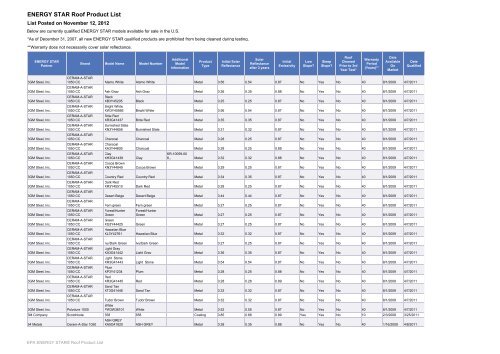

Hot mopped evaloy fleeceback roof system. This can assure compatibility with the underlying roof system in a re cover over a built up or modified bitumen system. The hot mopped roofing system utilizes sure seal black afx fleeceback or afx fleeceback plus membrane. The tpo membrane was first introduced to the roofing market in the early 1990 s as a more economical and efficient alternative that was thought to replace pvc roofing products. Fleeceback afx multiple ply epdm tpo hot mopped cold applied adhered specification and details 3 part csi format 3 part csi format specification for carlisle s adhered multiple ply fleeceback afx epdm tpo hot mopped cold applied roofing systems.

Amount of dupont elvaloy kee ketone ethylene ester polymer to. Ensure plasticizer retention extend roof life exceeded 40 000 hours of accelerated weathering testing astm g 154 requires 5 000 hours and to. Hyload h150e is a hot applied elastomeric membrane manufactured in a process that blends coal tar pitch with dupont elvaloy kee and is reinforced with dispersed polyester fibers. The hot mopped roofing system utilizes sure weld white afx 120 fleeceback or sure weld afx 135 fleeceback membrane.

The fleece allows for application of the membrane in hot asphalt. Applying the hot mop in progress is the second step to a general re roofing process acting as a secondary barrier between dry materials and tiles. The hot mop roof bur installation job can be completed within 2 to 4 days depending on the size of the roof and the number of installer we ve put on the job. After the roof system is selected the specifics of the system such as deck type insulation type s and thickness fastener patterns and warranty requirements are developed and details are designed.

This membrane is composed of three layers. The fleece backed membrane is fully mopped to an acceptable existing roofing membrane structural concrete deck base sheet or hp recovery board with type iii or iv asphalt or modified asphalt. This unique formulation combines the time proven characteristics of coal tar pitch with the advanced technology of dupont elvaloy to provide a high performance roofing membrane. To begin the hot mop process a layer of hot asphalt will be spread on top of the roof s base sheet.

Can be used as a cap sheet in bur and sbs systems when adhered using hot asphalt. The hot asphalt is laid out evenly with a large heated mop over the surface. Adjoining sheets of membrane are spliced. The fleece backed membrane is fully mopped to an acceptable existing roofing membrane structural concrete deck base sheet or hp recovery board with type iii or iv asphalt or modified asphalt.