High Temp Laminating Epoxy

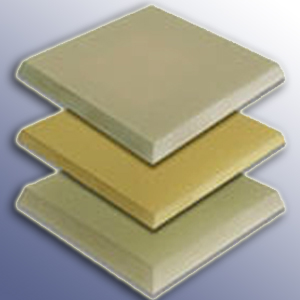

The high temperature system consists of a surface coat epoxy laminating epoxy and an infusion epoxy.

High temp laminating epoxy. Gel time 90d shore hardness. Black lightly filled high temperature epoxy laminating resin designed specifically for demanding high performance composite tooling. Renlam 4014 ren1500 aluminum filled high temperature laminating system gray. High temp laminating epoxy epoxamite ht high temperature laminating epoxy is a water clear uv resistant laminating epoxy that resists high temperatures up to 300 f 149 c when properly cured.

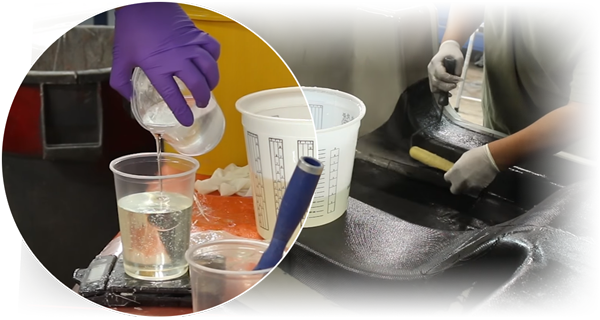

High temp laminating epoxy water clear uv resistant laminating epoxy that resists high temperatures up to 300 f 149 c when properly cured. Ultra low viscosity ensures uniform wetting out and fast penetration of reinforcement materials during hand lay up or vacuum infusion processes. Rdr 3250 is an unfilled clear epoxy room temperature curing laminating system used in high temperature and room temperature applications. This epoxy laminating system will gel hard in 24 to 36 hours at 77 f.

This system is tough strong has good heat distortion chemical resistance and excellent adhesive qualities. Pt2846 has good heat resistance making it capable of providing excellent long term service in today s higher temperature curing cycles. Pt2876 an unfilled amber epoxy laminating system designed for the highest service temperature applications. Pot life is 1 hour and cure time is 24 hours at 73 f 23 c post cure required see post cure schedule.

As with most high temperature systems. The resin has a medium low viscosity and when combined with the. Allow 3000 3120 high temp industrial epoxy to gel at room temperature before initiating an oven post cure. Freeman 917 economical high temperature epoxy laminating resin.

4 000 cps viscosity 52 min. Gel time 92d shore hardness. Renlam 4005 ren 1500 unfilled high temperature laminating system amber 1900 cps viscosity 50 min. Mix ratio by weight 100 18.

Pt2846 is an amber unfilled high temperature epoxy laminating resin designed specifically for demanding high per formance composite tooling. Pot life 77 f 90 120 minutes. For applications where continuous service temperature is over 250 f a post cure is mandatory. Pt2848 has good heat resistance making it capable of providing excellent long term service in today s higher temperature curing cycles.

Applications include making high temperature pre preg parts bonding fixtures vacuum form molds and prototype injection molds. Good handling and fabric penetration and very high physical properties. When combined to manufacture composite parts they can be demolded after 24 48 hours at room temperature before a freestanding post cure.